So you’ve taken the plunge and gifted yourself a one-of-a-kind Damascus Steel knife. First off, congratulations: in addition to their striking appearance, true Damascus knives are fantastic to work with due to their typical full tang construction.

Even though these blades look like something out of a high fantasy novel, however, they still require careful maintenance—especially regular sharpening. We’ve given you the full rundown on Damascus knife care: from cleaning to storing, here’s how you can keep these gorgeous blades in museum-worthy condition.

Understanding Damascus Steel

Damascus blades were originally made using a type of steel called wootz, considered to be the first high-quality steel ever produced. Wootz is thought to have originated in India prior to 500 AD, and involved melting iron together with high carbon materials like charcoal to produce cakes of hard yet flexible steel. When these cakes were heated and beaten, they formed complex wavy patterns—the unique patterns Damascus knives are known for—on the surface of the steel.

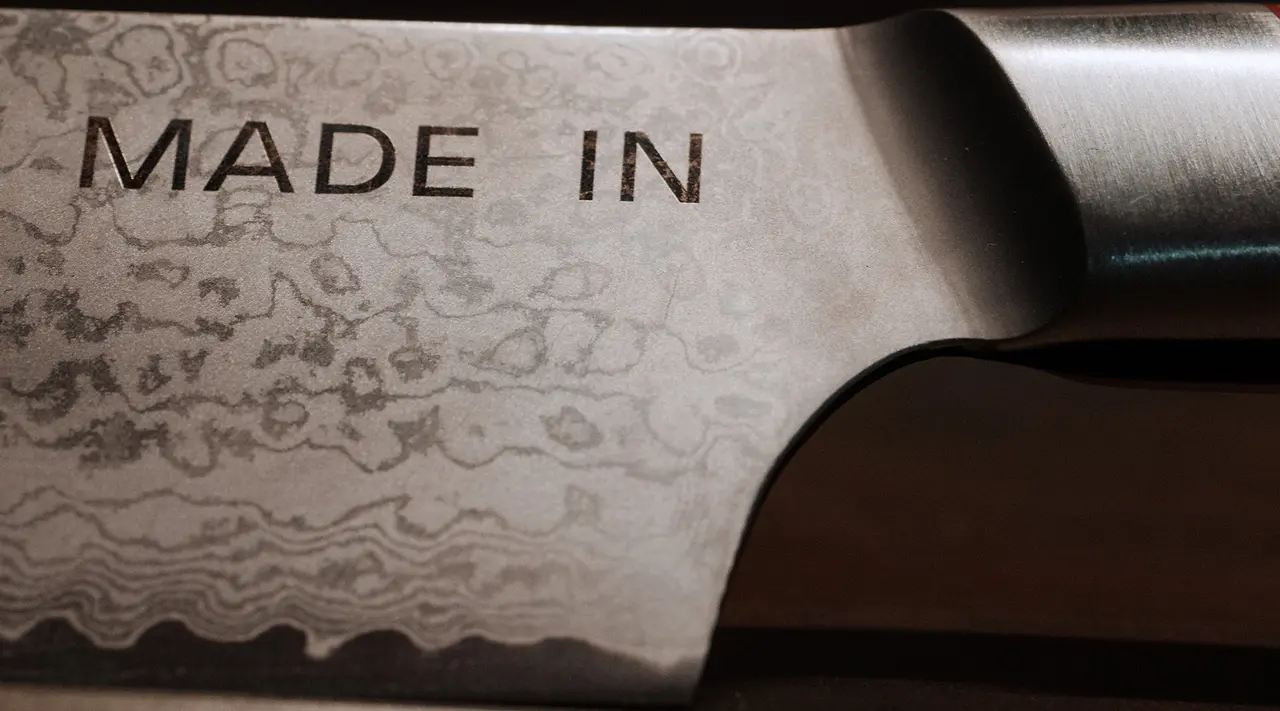

While the knowledge of how to make “true” wootz steel is thought to have completely died out, modern knifemakers are able to replicate the same ripple-like patterns using a process called pattern welding. This process yields an incredibly strong yet flexible blade with a unique surface pattern, and one which knife enthusiasts are happy to pay sky-high prices for the pleasure of collecting.

Composition and Properties

Like we mentioned above, Damascus steel knives were historically made using a high carbon steel alloy called wootz. These days, however, Damascus knives can be made from a variety of materials, in different combinations: our Damascus Steel Knife Collection, for example, is made using high-carbon VG10 steel, which is harder and holds an edge longer than knives with a smaller proportion of carbon.

No matter the composition of your knife, however, you should always check to make sure you’re buying a fully pattern welded Damascus steel blade. Like snowflakes, no two Damascus knives are exactly alike: each features a totally unique surface pattern. Suspiciously cheap knives—or knives with an overly uniform-looking pattern—might be superficially etched.

Importance of Sharpening Damascus Steel

In general, we don’t recommend using any knife that hasn’t been sharpened in a while. Not only is it tedious to try and chop up a pile of carrots or debone a chicken with a dull blade, but it’s actually pretty dangerous: if you’re forced to put excessive pressure on the knife, it can slip off of whatever you’re cutting and cause serious injury.

The same goes for Damascus knives: make sure to sharpen your blade at least once or twice a year for casual use, more often for heavier use.

How to Sharpen Damascus Steel Knives

There’s no actual difference between sharpening a Damascus Steel knife and sharpening any other type of knife. We strongly recommend sharpening manually, using a whetstone—aka, a sharpening stone—rather than an electric sharpener, which can be rough on your blade.

How to Sharpen Using a Whetstone

To get started, you'll first need a whetstone: we recommend one with an 800 to 1,000 grit for regular sharpening and maintenance. In addition, you’ll need a towel or dishcloth for stabilizing the stone on the table while you’re working, as well as a bowl or tub for submerging it in water.

1. Soak the Stone

While some stones—called oil stones—need to be coated with a layer of honing oil prior to use, whetstones typically need to be submerged in water for anywhere from 10 to 45 minutes. Make sure to check the soaking instructions for your particular stone.

2. Set Up Your Station

Lay down your towel, then set up your whetstone so that it’s perpendicular to your body.

4. Determine Your Angle

Knives typically feature a slight bevel, or angle, right next to the very edge of the blade, which makes for a sharper and more precise cutting edge. Before you begin sharpening, you’ll need to find the exact angle of your blade: your knife’s manual should include this information, but if not, this video offers a step-by-step guide for beginners. For example, our Damascus Steel Knives have a 15-degree angle.

5. Start Sharpening

Place your blade on the stone so that the heel lines up with the far edge of the stone. Hold your knife at the correct angle, then, using even pressure, draw the blade down and across the stone in a rounded motion toward your body. Stop when the tip is flush with the edge of the stone that’s closest to you. You should be gripping the handle with one hand, resting the fingers of the other hand on the flat part of the blade.

6. Repeat

Repeat this same motion 10-20 times until a burr forms along the edge, and a thin layer of grayish water develops along the side of the blade. Flip the blade to the other side: aligning the heel with the bottom edge of the stone, repeat the whole process once more, pushing the blade away from you in the same rounded motion.

7. Smooth and Polish

Repeat steps 4 through 10 using a finer grit stone. This will further refine your blade and leave you with a polished-looking finish.

Once you’ve finished sharpening your knife, you can test the sharpness using the tomato test or the paper test. With either of these, the blade should slice cleanly through with minimal resistance if it’s been properly sharpened.

When to Hone

In addition to sharpening, we also recommend regularly honing your blade. As opposed to sharpening, which involves removing microscopic layers of metal from your blade to reveal a new, sharper edge, honing involves realigning the blade by smoothing out any dents or dings that may have formed through use. Check out our post on honing vs. sharpening for more information.

Common Mistakes to Avoid

These are some of the most common knife-related pitfalls.

Improper Angles

Always make sure to follow the correct angle when sharpening your Damascus knife. Knives often have a bevel angle of 15 to 20 degrees—your knife’s manual should state the specific angle. Many whetstones also come with angle guides to help you.

Using the Wrong Tools

We don’t recommend using a file or overly coarse stone for sharpening any kind of knife—and definitely not for Damascus knives. These tend to shave off too much of the blade material, which means you’ll have to replace them sooner.

Over-sharpening

Make sure to space out your sharpening sessions: unless you’re a line cook or someone who uses their knife for hours per day, there’s no need for weekly (or even monthly) sharpenings. Much like using one of the above mentioned tools, oversharpening will quickly wear down your blade and necessitate replacing your knife after just a few years.

Maintenance Tips for Damascus Steel

Once you’ve added a Damascus knife to your collection, it’s important to maintain it between sharpenings to keep it in tip-top shape.

Regular Care and Cleaning

You shouldn’t need anything stronger than a gentle dish soap and soft sponge to clean your knife on a daily basis. Also, never leave your knife to soak, or forget about it in a sink full of soapy dishes: this can cause your knife to rust.

Storing Your Knives

Proper storage can help keep your knives sharp—and your fingers intact. Keep your knife safely tucked away in a drawer organizer, knife block, or—if you’re transporting your knife from one site to another—a sturdy knife roll. Tossing your unsheathed knife into a drawer with other utensils is a recipe for a dull, dinged up knife, and can cause serious injury to anyone reaching in to grab something.

Periodic Sharpening and Honing

Honing is a great way to freshen up your blade between sharpenings. Again, since you’re not actually shaving off any blade material, you can theoretically do this as often as you like—even every day, depending on how often you use your knife.

Ready to Shop?

Just like any high quality blade, Damascus knives work best when they’re carefully sharpened and maintained. And while you don’t need to don a pair of gloves every time you handle your knife, we definitely recommend doing a little extra homework using it for the first time: your hard work will pay off in spades.

Our new collection of Damascus Steel Knives are made in Seki, Japan by a factory with over a century of knife (and sword) making experience. The steel is compressed and folded into 66 total layers, so each knife sports a completely unique Damascus pattern. Add these collectors’ items to your knife set today to see the difference they can make in everyday chopping, slicing, and mincing.